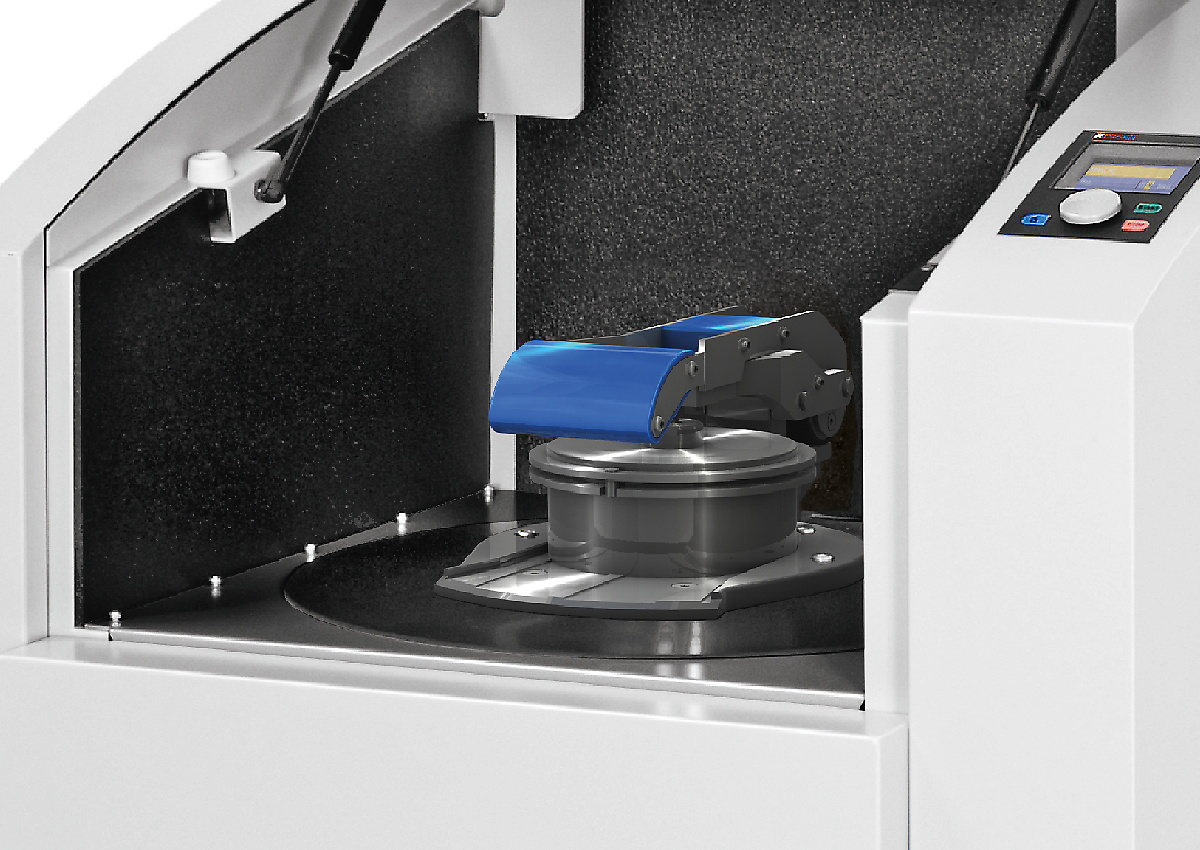

No grinder can beat the speed of a Vibratory Disc Mill when it comes to preparing samples for spectral analyses. RETSCH’s Vibratory Disc Mill RS 200 is ideally suited for fast and reproducible pulverization of hard, brittle and fibrous sample materials to analytical fineness.

The RS 200 runs steadily and smoothly, even with heavy grinding sets and at maximum speed thanks to its powerful Stabilized-Plane-Drive. It achieves grind sizes between 20 and 100 microns within seconds and with excellent reproducibility.

Grinding sets are available in a variety of sizes and materials. A set of sensors will recognize jars of tungsten or agate and automatically sets the maximum permissible speed, ensuring optimum results while protecting the material.

| Applications | size reduction, mixing, triturating |

| Field of application | construction materials, environment / recycling, geology / metallurgy, glass / ceramics |

| Feed material | medium-hard, hard, brittle, fibrous |

| Size reduction principle | pressure, friction |

| Material feed size* | < 15 mm |

| Final fineness* | < 20 µm |

| Batch size / feed quantity* | 15- 250 ml depending on size of grinding set |

| Speed at 50 Hz (60 Hz) | 700 – 1,500 min-1, continuously adjustable |

| Material of grinding tools | hardened steel, tungsten carbide, agate, zirconium oxide, steel 1.1740 (for heavy-metal free grinding) |

| Grinding jar sizes | 50 ml / 100 ml / 250 ml |

| Setting of grinding time | digital, 00:01 to 99:59 |

| Storable SOPs | 10 |

| Drive | 3-phase asynchronous motor with frequency converter |

| Drive power | 1.5 kW |

| Electrical supply data | different voltages |

| Power connection | 1-phase |

| Protection code | IP 20 |

| W x H x D closed | 836 x 1220 x 780 mm |

| Net weight | ~ 225 kg (without grinding set) |

| Standards | CE |

There are no reviews yet.